Strong typhoon "Meihua" is coming, Jiangsu, Zhejiang and Shanghai will usher in heavy precipitation, quickly Get air compressor anti-soaking manual!

Release time:

2023-04-13

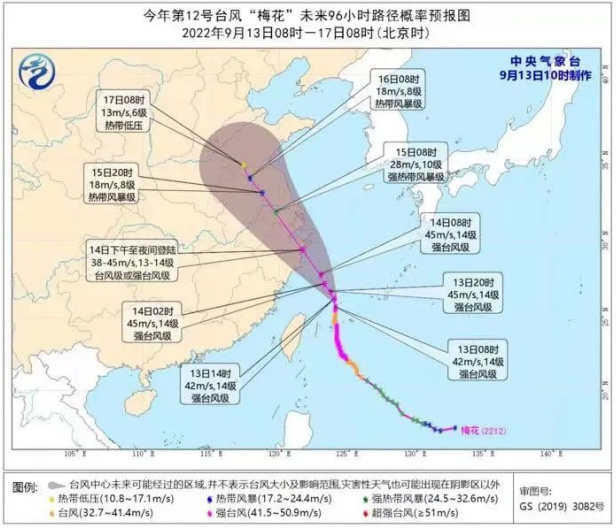

It is reported that the 12th typhoon this year "Meihua" will be in the afternoon of the 14th to the night in Zhejiang Wenling to Zhoushan coastal areas, after landfall "Meihua" continue to move northwest, the intensity gradually weakened. Affected by the "Meihua", Jiangsu, Zhejiang and Shanghai will be affected by heavy rainfall.

It is reported that the 12th typhoon this year "Meihua" will be in the afternoon of the 14th to the night in Zhejiang Wenling to Zhoushan coastal areas, after landfall "Meihua" continue to move northwest, the intensity gradually weakened. Affected by the "Meihua", Jiangsu, Zhejiang and Shanghai will be affected by heavy rainfall.

In addition to the violent storm that will occur with the landfall of a typhoon, there will be a great possibility of secondary disasters (such as urban flooding) once the city's sewage system is overloaded, which will have a great impact on people's production and life. In the face of potential secondary disaster risks, how can we minimize the impact of standing water on air compressors?

Machine head soaking

For the head soaking water, we should first disassemble the intake valve, if there is mud and other debris into the head, must be disassembled to thoroughly clean the interior and then reassemble. If only a small amount of water, available diesel fuel or kerosene poured into the rotor to rotate the water can be discharged, and then finally pour oil into the cleaning oil discharge.

Control class electrical soaking water

For the inverter, controller class and other electrical parts soaked in water: first open the inverter panel, the inverter internal dry with a dry towel, and then blow dry with a small blower drive board, motherboard, lightning protection board, inverter module and fan, etc., and then use the washboard water or alcohol (note not to use banana water) scrub once, and then blow dry with a small blower, about an hour to scrub again, and then blow dry with hot air. After cleaning and drying the inverter installed do not immediately turn on the machine, power on half an hour without abnormalities and then turn on the machine to run.

Motor soaking

For the motor (including fan motor) soaking water: remove the motor end cover, clean up the water, such as mud into the mud, be sure to clean the mud, then blow dry with a blower, and then drying: low temperature pre-drying, temperature control at 50 ~ 70 ℃, drying time of 8 ~ 14h. high temperature drying; temperature control at 80 ~ 100 ℃, drying time of 1h. short drying time for small motors, large The drying time of the motor should be longer. Measure the insulation resistance value of the winding with 500~1000V insulation resistance meter every 1h, for the insulation resistance value of the dried motor should be more than 5MΩ, if it is not reached, it needs to continue drying.

Contact professional after-sales service staff

It is recommended not to repair the soaked air compressor without authorization, but to contact the local professional after-sales service center to avoid unnecessary maintenance costs and equipment losses.

Related news