After reading this article you will know how to choose the pharmaceutical industry air compressor!

Release time:

2023-04-12

Compressed air in pharmaceutical enterprises is mainly used in liquid preparations in the filling machine, solid preparations in the granulator, slurry machine, filling machine, packaging machine, printing machine, extraction process in the extraction tank. In addition, there is also the use of gas in the laboratory, powder material conveying, drying, blowing material blowing, pneumatic instrumentation components, automatic control with air.

Compressed air in pharmaceutical enterprises is mainly used in liquid preparations in the filling machine, solid preparations in the granulator, slurry machine, filling machine, packaging machine, printing machine, extraction process in the extraction tank. In addition, there is also the use of gas in the laboratory, powder material conveying, drying, blowing material blowing, pneumatic instrumentation components, automatic control with air.

Because compressed air for formulation comes into direct contact with pharmaceuticals, compressed air must be purified; it must be verified to prove that the system meets production requirements; in addition, it must pass a GMP certification inspection. Compressed air for preparation, such as air for drying and pressing materials, must control the content of oil, water and solid particles and biological particles in compressed air, and also requires odorlessness.

How to select the model?

For compressed air for pharmaceutical use, the recommended content of particles, water and oil is executed according to ISO 8573-1 "Compressed Air Quality Class" in class 2-2-0. The purification process is recommended according to: oil-free air compressor → storage tank → gas and water separator → refrigerated dryer → precision filter → adsorption dryer → dust removal precision filter → activated carbon filter → high-temperature sterilization filter → air service.

(Chenn's Oil-free Scroll 4-in-1 Integrated Compressor)

Why choose Chennai oil-free scroll air compressor?

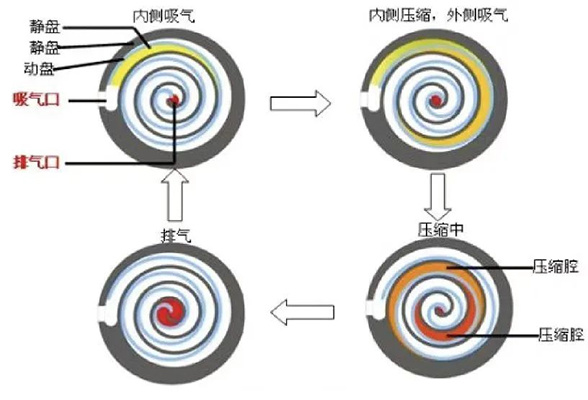

Oil-free scroll air compressor compared with the traditional air compressor, has a novel structure, small size, light weight, low noise, long life, smooth and continuous air delivery, easy operation, low maintenance costs and a series of excellent technical performance, known in the industry as the air compressor without maintenance and new revolutionary air compressor.

(Working schematic)

Related news